All You Need To Know About Saksham Industrial Engineers

SAKSHAM has been a one-stop solution for powder handling by supplying unloading, mixing conveying, and packaging projects / products for the processing of bulk materials since 2011. A good combination of innovation, operational safety and service means more value and success for our customers!

Customization, Conceptualization & Commissioning as a pillar of SAKSHAM, led to the successful completion of more than 100+ projects in India. The main Industrial parts by us are Construction, AAC Block, Cement, Foundry, Detergent, Mining, food Packaging, and chemical etc.

We introduce ourselves as a Technical Consultant & Competent Supplier of –

- Bulk Powder Handling Equipment for Conveying and Feeding

- Dust Filtration Systems

- Silo Accessories and Safety System

- Solid Extraction And Discharging Equipment

- Valves and Actuators

- Vibratory Equipment

- Aeration Systems

- Dosing and Meeting Equipment

Our dedicated employees work round the clock to inspire our customers. Our reliable and trustworthy consulting service and monitoring of the personal project during the configuration and realization of systems for the processing of bulk materials are one cause for high customer satisfaction.

Believing in Innovation for the future

Customization, Design and commissioning the three pillars of Saksham have Innovation as a belief system with set solutions to meet customer’s expectation, since 2011. The outstanding services offered also signify that a Saksham is an investment in a successful future. The Saksham service is always available to customers, providing technical studies and services in connection with maintenance, repair and upkeep.

How You Benefit

Made by Saksham means fast ROI, low-maintenance costs as well as high availability of the systems.Our process steps contain

- Reception of the raw materials

- Pneumatic Conveying

- Feeding

- Mixing processes

- Filling

- Automation

Let’s see our supplied products which are highly liked by clients….

OUR SUPPLIED PRODUCTS

Our strong domain expertise makes us able to bring onward a broad assortment of innovative product range, which includes:

1. Pneumatic Vibrator

The pneumatic vibrator is a flexible piece of equipment that is important to numerous industries. In construction for instance, the pneumatic vibrator is utilized to remove excess moisture and air packets from freshly poured concrete ensure that the end result is consistent, attractive and especially, safe. In agricultural settings these easy-to-use vibrators are responsible for emptying silos, among other things, while in pharmaceuticals a pneumatic vibrator can divide fine powders or be used as a feeding mechanism.

2. Bin Activator

Bin Activators are used in a variety of industrial applications to facilitate the extraction of powdered or granular materials from a silo or hopper. The use of this equipment makes sure optimum feeding of the material according to a “mass flow” condition, thus avoiding closing or rat holing phenomena.

3. Dust Conditioner

Dust Conditioner is used to mix powder, sand or other granulates materials with water so as to fix the dust. It is the most economical, advanced technology for dust processing equipment that is very easy to install. Dust conditioner can mix as well as humidify the dust at the same time.

4. Electromagnetic Vibro Feeder

The Electromagnetic Vibro Feeders provided by us are high frequency reciprocating machine able to conveying bulk materials between different processes. These electromagnetic feeders can handle all types of material irrespective of their nature such as hot, damp etc. These can be used in various processes such as sprinkling, weighing, mixing etc. These are supplied with base mounted, over hanging as well as combined single magnet drive. These can also be availed with dual twin magnet drives and multiple drives to be used as vibrating conveyors.

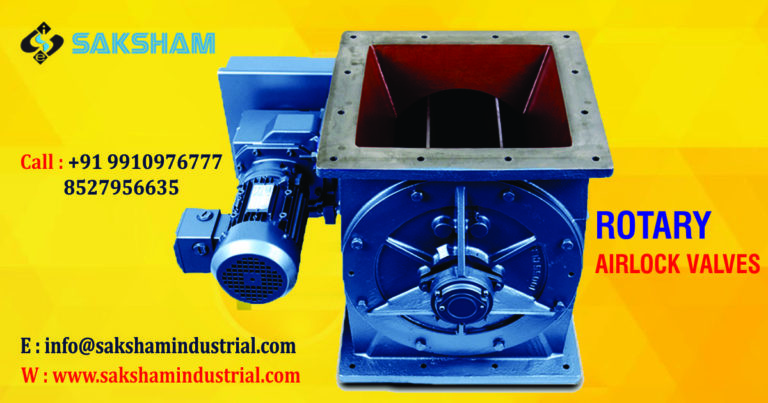

5. Rotary Airlock Valves

Rotary airlock valves are additionally called rotary feeders, rotary valves, or just rotary airlocks. Used in both pressure style and vacuum style pneumatic conveying systems, these valves provide as a “lock” to stop air loss while at the same time performing very important materials handling functions. Although simple, the rotary airlock valve is a critical component to the efficiency of a conveying system. It is important to keep in mind that not all rotary valves are essentially rotary airlock valves – however virtually every rotary airlock is rotary valves.

6. Diverter Valves

Diverter Valves are vital components in bulk solid handling systems. They are hardened to shut off flows, adjust flow speeds as well as change conveying directions of powders, pellets and granular bulk materials. A wide range of diverter valves is available for handling dry bulk material in pneumatic transmission & gravity flow applications. Besides, standard production range, custom-designed valves are available for wide variety of applications.

7. Aeration Nozzles

Aerator Nozzles stand for the most inexpensive solution to make sure material flow from silos, bins or hopers. Aerator Nozzles can be easily built-in or retrofitted in existing installations. The engineering polymer casing, co-molded through a sintered nozzle has to be screwed on a supplied steel nipple which previously has to be welded on the outer of the silo, bin or weigh hopper cone. Then, connection with the dense air supply has to be carried out. Their small footprint makes Aerator Nozzles mainly appropriate for retrofitting. Aerator Nozzles are utilized with fine powdery materials, for example cement, lime, and similar powders.

SAKSHAM is a leading engineering and manufacturing company in India with a focus on providing sustainable as well as reliable solutions to its customers across the world in the domain of powder and bulk solids. With consistent technology upgrades we have satisfied our customers developing challenges and requirements.