What information are needs to know about Diverter Valve?

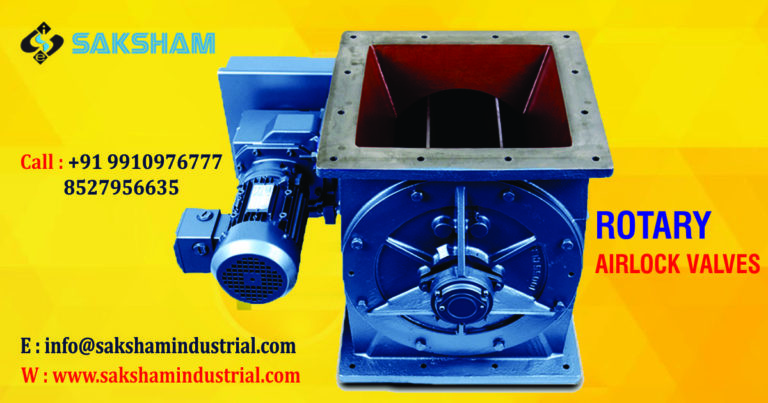

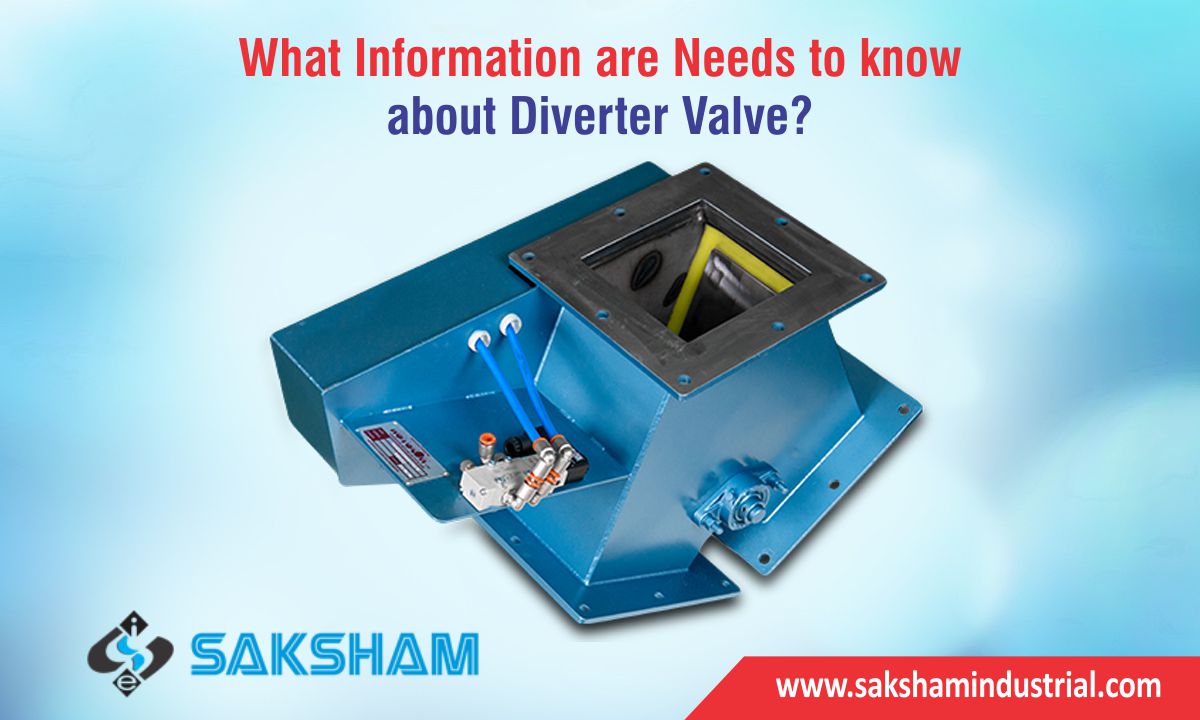

Saksham Industrial Diverter Valves offers an effective method for directing product flow from a single source to numerous destinations. Perfect for batch systems. It can also be utilized as a two in to one gathering hopper.

Intended to handle the gravity feed to dry powders, pellets, granules, or some other free flowing product. Valve is dust tight inside to outside. Flap-gate minimizes leakage between system legs. Contact factory representative for pressure & temperature limitations.

Strong Overall Construction Will Make Sure Dependable Service

Standard construction is heavy measure middle steel. Additionally accessible in stainless, aluminum & abrasion resistant steel.

It can be operated manually or automatically with air or electric actuators. Optional limit switches point out which leg is open to product flow.

Air actuator incorporates cylinder, 4 way double solenoid valve, and air filter / regulator / lubricator & flow control valve.

All controls are factory mounted and adjust. Standard flanges in sizes 4” through 24” match pattern of square design SAKSHAM rotary airlock feeders and other Saksham system components.

Features & Benefits of Diverter Valves

- 2 ways, Y style, gravity valve gives automatic control of bulk material flow direction; get better effectiveness of material feeding and loading operations.

- Available in 4 heights, from 165/16” to 24”H, & 4 square-flange sizes from 6” to 12”.

- Accessible in 30 degree or 45 degree outlet angles.

- 10ga carbon steel housing structure; long-lasting carbon steel flappers by neoprene seal & carbon steel seats.

- Air control package incorporates solenoid, fitting, and tubing; pre gathered and prepared for start-up.

- Superb performance in high-temperature applications up to 500°F.

Options of Diverter Valves

- Round flange design: available in 4 heights, from 247/16” H to 317/16” H & 4 flange diameters from 6” to 12”.

- 3 way diverter valve design.

- Custom outlet angle construction, particular to application requirement.

- Valve housing & flapper construction 304 or 316 stainless steel, carbon steel, or aluminum.

- Abrasion opposed to steel flappers.

- Chain drive geometer & cam design.

- Manual actuator.

- Dual side access panels for easy arrive at into internal housing areas; or single, removable back panel.

- NEMA 4 Timer; 115-50 / 60-1 electrical; power on light; on /off switch; timer arrangement to operate up to 6 valves.

SAKSHAM INDUSTRIAL is experts in powder handling components and material handling systems. Formed in 2011 we manufacture a extremely comprehensive range of products as well as Rotary Airlock Valves, Diverter Valves and Screw Feeders for use in a broad range of industries, including food, chemical, plastics, minerals, power and the energy industries.

Products are constantly intended to your particular application and specification requirements, and our engineers will work with you to develop a custom solution for even the trickiest application. The company belief is to supply customers with products which conform to the most excellent standards and are fit for their planned purposes.

We have earned a reputation throughout the industry for excellent problem solving capabilities, superb quality and customer service. We understand that high levels of quality are accomplished through communication, cooperation, careful planning, & excellent manufacturing practices.

Our experts are available for you to contact at any time & can be quickly on site. Contact us @ +91-9910976777 / +91-8527956635.