What is Automatic Bag Slitting Machine and it’s features?

The Automatic bag slitter is a flexible Automatic Bag Emptying Machine intended to open bags, empty its stuffing and packed in. The empty bags in the continuous and dust-free treatment of a wide range of singles or multi-layered bags expect jute bags.

It has intended to deal with a scope of bags containing powder or granular materials. A poisonous or toxic nature is completely enclosed system to prevent atmospheric contamination.

Contingent upon the properties of the product and the state of bags, capacities as much as 40 tons per hour can obtained.

The Automatic Bag Slitter Machine consists of –

- Fundamental feed conveyor,

- Self-aligning rotating knives,

- Unbending slitting chamber with receptacle vent filter,

- Squander bag separator & compactor and release hopper.

Bag handling limits ranges from 100 to 800 bags per hour of 25 to 50 kg bags.

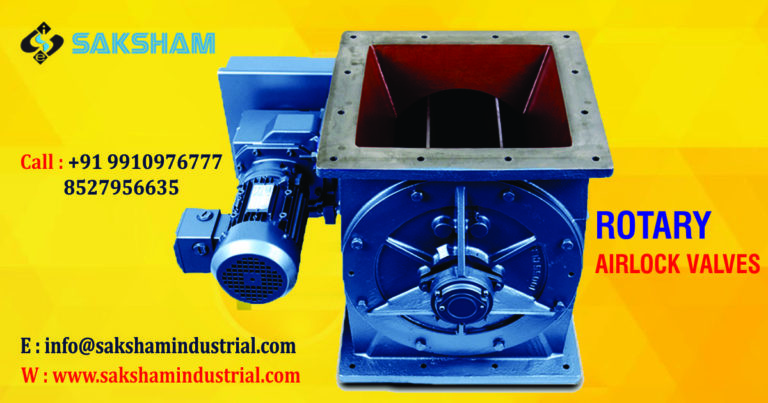

The SAKSHAM automatic bag slitting machine coupled into the down-stream process. The degree of computerization can customized to suit every application and financial plan.

The SAKSHAM bag slitter fitted with a self-sufficient control system. So without difficulty can installed & incorporated into existing or new process systems.

Read on for more information about Automatic Bag Slitting Machine| Automatic Bag Emptying Machine

SPECIAL FEATURES:

- Versatile – Wide Range of bag sizes can handled containing granules and power materials.

- Safe and Clean – Works in a completely enclosed system, reducing atmospheric pollution. Clear cutting action minimizes product contagion.

- Durable – Quality construction and long blade life.

- Easy to Operate – Effortless trouble free processing.

- Cost Effective – Low cost installation and maintenance.

TECHNICAL SPECIFICATION:

- Moc – Available in mild steel construction with optional coatings. And stainless steel with optional finishes.

- Capacity – 100 to 800 bags/hour of 20 to 50 kg.

- Type of bags – Expect jute made all other material bags.

- Material Retention – 3% Maximum

MACHINE SPECIFICATION:

- Bag sizes – up to 70mm X 400mm X 145mm (Weight – 50Kg/Kg)

- Least Power Source – 11 KW

- Emptying efficiency – 97% – 99% depending on flowing characteristics of the material.

- Particle Sizes – Powder & pellets of free flow characteristics.

- Accessories – Feed Conveyor, Vibro sieve, platform

Furthermore, Automatic Bag Slitting Machine consists of a bag feeding and bag cutting system. At the beginning followed by a Rotating Cylindrical Screen which forces the bag to be empty completely.

Get In Touch With SAKSHAM to Get Specialized Technical Services!!

SAKSHAM Industrial Engineers is a #1 youthful enterprise in Noida. It’s as well-known supplier of value products & as a technical expert.

We are unite with top European and Indian producers and stand for then in India with a satisfactory team for Marketing, Sales and Services help.

Major Industrial areas served by us are:

- Construction

- AAC Block

- Cement

- Detergent

- Foundry

- Mining

- Pacing

- Food

- Chemical etc.

We try now and again in creating awareness and keeping the company at average to the latest development in our area of working.

We also save stock of consumable spares for the equipment supplied by us for cooking the instant requirements of customers.

With enough professional and technical experience, loyalty to quality and hard work. We have achieved a strong grip in the market.