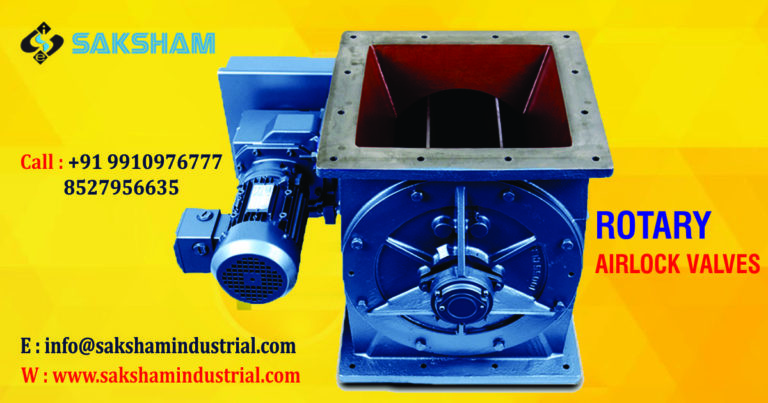

WHAT IS ROTARY AIRLOCK VALVE AND HOW DOES IT WORK?

A Rotary airlock valve is a device which widely used in material handling industrial process. It is used to convey material continuously, and maintain a constant air pressure in between inlet and outlet ports which the help of blade rotor while sealing in air leaks. These valves are a critical component in many material handling systems. The rotary airlocks are not only control the feed rate also minimize the air leakage between equipment from dust collectors to pneumatic conveying systems. In dust collection systems the rotary airlock allows continuous product discharge without having vacuum to dump the accumulated material.

Rotary Air-lock Valves are mainly used at the bottom cyclone, Dust Collectors or Feed Hoppers to discharge materials at a controlled rate. The Rotary Air-locks provide dependent service in high pressure and temperature or other severe service conditions. These airlock valves can be used in various industries like food, plastics, chemical, mining, baking, cement and paint.

Design Description: A metal blade of a airlock valve rotate during the operation, the materials being handled enters the pockets through inlet port before rotating and then exit through the outlet port. The air seal between inlet and outlet port that allow to the materials visit downward through the valve from inlet to outlet port. Material moved continuously constant air pressure between the port.

Types of Rotary Air Lock Valves:

Drop through Rotary Valve: This valve Available with square inlet and in circular inlet consist of tubular stainless steel casing, this horizontally mounted rotor. It is control to discharging and feeding of granular materials from silos, pneumatic conveying system etc.

Blow-Thru Valves: This valve designedfor pneumatic applications conveying line which require discharging into it. These Airlock valves are usually opted for the free-flowing materials which require clearing of rotor vane pockets.

Standard Duty Rotary Valves: Heavy-Duty rotary airlock is an ideal option for handling many dry, free-flowing powders, and the applications which do not need to have special robust valves and use standard airlock valves.

Uses:

To feed material from bin or hoppers.

To deliver fines from the collector while sealing against air leakage.

To feed material to pneumatic conveying line against pressure.

Rotary Air Lock Valves used to introduce materials into conveying system.

The valves provide reliable service in high pressure and temperature.

Rotary Air Lock Valves are Robust and compactly designed to attain higher productivity.Applications:

Dosing the material from a silo to a weigh hopper or conveying line.

Maintains airlock between a screw conveyor and conveying line.

Maintains airlock between a mixer and conveying line.

Smooth discharge of product from a hopper.

Blow through Rotary Valves used for accurate pneumatic conveying.