What is the Performance Features and Benefits of Micro Batch Feeder?

The Micro Batch Feeder for continuous volumetric feeding of fine or grainy materials comprises of a steel reinforced SINT® engineering polymer body (selectively body complete fabricated stainless steel), a flat mounted rotating agitator tool, a feed screw beneath the agitator tool, a feeder pipe contiguous the protruding feeder screw, one drive connect each for agitator for feeder screw.

Tests on product stream and material pressure have been carried out to build up ideal body geometry. Agitator & feeder tool geometry and materials have additional been tested before picking an optional steel and engineering polymer compound.

MBF series Micro Batch Feeder are supplied in food-grade adaptations with FDA approval on request.

Function

Micro-Batch Feeders for powder along with granular product transportation are particularly reasonable for unsuccessfully flowing materials which are inclined to clog, along with adhesive products. Fed through a bag opening hopper, a bulk bag discharger, or one more feeding device, the agitator tool manage to keep the material flowing reducing simultaneously the possibility of development of lumps or bridges.

The size of the product specific is of utmost significance when picking the kind of feeder screw. For instance, fine, heavy materials call for tapered screws with reduced pitch fights, while granular, lighter materials need standard pitch cylindrical screws.

Inadequately graceful products with cohesion or bridging problems are consistently fed into feeding zone by the combination shaft which is shaped according to the product properties. Depending on the user’s individual necessities, Micro Batch Feeder can be supplied with alternative feeder screws and blending tools and with a variety of accessories. Micro Batch Feeders have been effective operating in the following industries

- Building

- Plastics

- Chemicals

Performance and Technical Features & Benefits

- Body in SINT® engineering polymer from a casting process complete with stainless steel end plates (on the other hand whole body in stainless steel); all components exchangeable

- Feeder instrument with separates drive units

- 3 sized accessible; feed rates from 3dm3/h to 4,000dm3/h (0.001 to 2.4 cfm)

- Internal geometry of the body ensures free flow of difficult materials

- Minimum clearance between the screw flight and the feeder pipe guarantee high accuracy feeding

- Independent drive units make it possible to choose diverse drive power and speeds for blending shaft and feeder screw

- Wide variety of compatible feeder tools in SINT® engineering polymer or in stainless steel

- Flexibility in choice of micro-batch feeder generally reasonable for the material concerned

- Vast scope of exchangeable components’

- Easy and speedy maintenance because of small number of components

- High level of homogeneity of the feed material

- Easy and quick cleaning because of engineering polymer non-stick surface and fast access board

Options & Accessories

- Units in FDA approved food grade SINT® engineering polymer or totally in stainless steel

- ATEX zone 22 certification

- Vertical outlet

- Pneumatic activator / electric vibrator

- Feeding container: increase storage ability. One request accessible with stream aids

- Square sack feed hopper

- Round bag feeding hopper with independently determined vertical agitator tool for materials that tend to pack under pressure

- Feeding pipe line in standard or food-grade engineering polymer accessible on request.

- As an choice food grade requirements joined with “ATEX” similarity a model manufactured fully in stainless steel is accessible

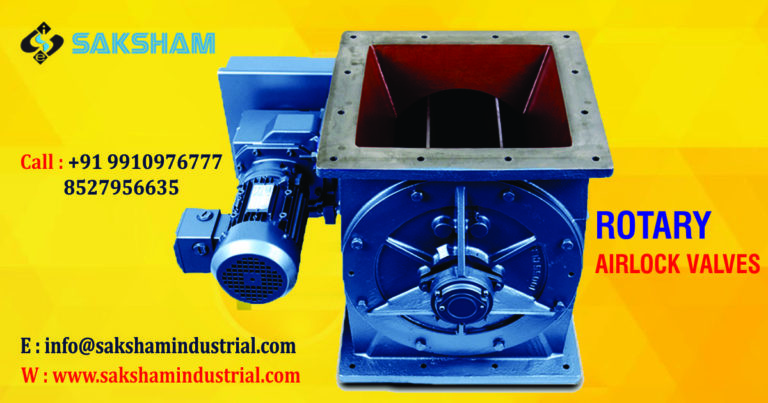

SAKSHAM has developed broad experience, reaching almost every area of the world, providing its customers with the most excellent products, innovative designs and outstanding service.

With this experience, we can give you with the bulk material processing ability that efficiently meets your requirements now and in the future.

Contact us today @ +91-9910976777 / +91-8527956635 to discuss your requirements…