What are the types of Screw Conveyor?

Screw conveyor used in the mechanical conveying fields are generally considered to have a difficult use. However, conveyor are really among the most economical methods you can use in the transportation field. In terms of cost, the conveyor are not preferred much in places where there is a long distance. Those looking at operating costs instead of investment costs prefer to use a screw conveyor.

Screw Conveyor have different areas of use according to feeding types. Some are used for dosing, some for feeding as well as some for effervescent function. You should carry out your transportation process in according to the capacity of the screw conveyor. If you do the transportation process with considering the capacity of the screw conveyor, you may encounter many problems during the work.

Screw Conveyor Types:-

If your place is short, you can utilize flexible screw conveyors. These conveyor have a taker function among the functions we have just mentioned. You can usually use flexible conveyor for unloading in bunker areas. The products that you will do the transport process will get better efficiency in powder materials. Efficiency of the screw conveyors depending on the properties of the product you are carrying. For this reason, you should choose augers suitable for the area you are using.

The efficiency of the conveyor may be more or less depending on numerous reasons. The product you are carrying, the use of a screw conveyor operator, and the like factors affect the operation of the screw conveyor. For this reason, it is important to pay attention to other things when using a screw conveyor. People with knowledge in the sector usually recommend flexible screw conveyors in terms of user-friendliness. Nevertheless, if you don’t use flexible spirals carefully, you will experience all kinds of problems.

Increased speed in the use of the screw conveyor can cause the area to exit from the product to close. This closure badly affects the screw conveyor’s leaves. The screw conveyor leaves break when harmfully affected by this situation. Fracture in the leaves significantly reduces the working efficiency of the screw conveyor. For this reason, you should pay attention to things such as high speed in the use of a screw conveyor.

#1: TUBULAR SCREW CONVEYOR / FEEDER

Tubular screw conveyor & feeder are manufactured from carbon steel with appropriate surface finishing. They consist of a tubular trough equipped with as a minimum one inlet and outlet spout, a welded flange at each tube end, helicoids screw flighting welded on a center pipe with a coupling bush at every end, two end bearing assemblies complete with self-adjusting shaft seal, several intermediate hanger bearings depending on the overall length of the conveyor.

#2: TROUGH SCREW CONVEYOR / FEEDER

These trough screw conveyor generally used for industrial process for conveying or feeding powder or granules. Obtainable in ‘U’ and ‘V’ shaped trough with continuous flight welded on center pipe with bush & having at least one inlet and finish bearing to each trough.

#3: VERTICAL SCREW CONVEYOR

Vertical screw conveyor are the mainly economical as well as space saving solution for transferring powders or granular materials from a lower to a high level. The bulk material withdrawn from a silo, hopper, conveying or feeding device may be disassembled with a vertical screw into a weigh hopper, in one or more bins or silos, or into another conveyor or conveying system.

#4: LOSS IN WEIGHT FEEDER

A loss in weight feeder is a gravimetric metering device that receives material from an upstream supply and perfectly doses the material into a predetermined federate process, usually through a screw (helix), or vibratory tray. The product is discharged from the hopper by the metering device & the resulting weight loss per unit of time is dogged by the weighing and control system.

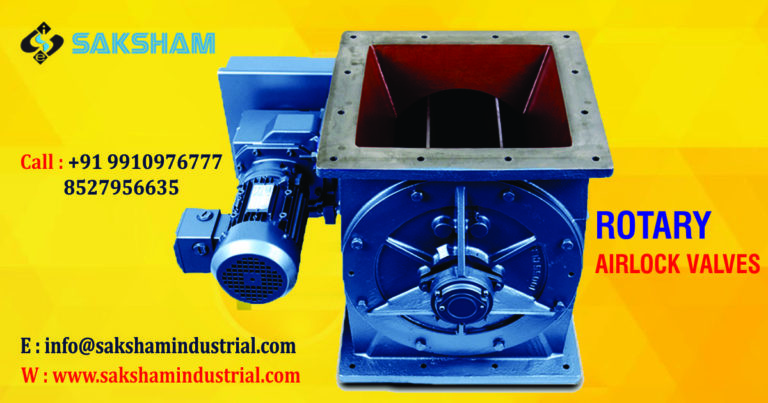

With extensive experience in bulk material handling industry, SAKSHAM has become one of the leading Screw Conveyor Manufacturer and supplier in India. We design and engineer different types of screw conveyors.

Get in touch with us at www.sakshamindustrial.com to learn more and call us @ +91-9910976777, +91-8527956635!